Call Us Today

+86-18817238309

Send Us

Floor 11th, Building A3, Tian'an Cyber Park,

Jiangyin, Wuxi, Jiangsu, China

Views: 0 Author: Site Editor Publish Time: 2024-12-26 Origin: Site

Mica paper is a mica product made of crushed mica or mica powder as raw material, which can replace natural mica as an industrial electrical insulation material through pulp, copying, molding, pressing and other processes

Mica tape is made of (mica tape machine), which is a kind of refractory insulating material, which is divided into double-sided tape, single-sided tape, three-in-one tape, double membrane tape, single membrane tape, etc. According to mica, it can be divided into: synthetic mica belt, phlogopite belt, and muscovite belt.

How to distinguish mica paper from mica tape?

Due to the low mechanical strength and mechanical strength of mica paper, it generally cannot be used directly. This is because the mica scales lack a large enough orientation force, and the recrystallization direction can not be very consistent, so the mica surface is easy to produce an entrance to introduce water, and the fresh surface of mica is easy to attract gases containing water, hydroxyl groups and its similar ions or molecules, which completely affects the close binding of mica paper, so mica paper needs to be made of adhesives and reinforcing materials to meet the different needs of all aspects, which is mainly used to manufacture insulating mica products and high-temperature resistant mica products.

The mica tape is an insulating material made of mica paper and glass fiber cloth, OPE film (oxide polyethylene wax) and other reinforcing materials with appropriate adhesives (silicone, etc.) after baking and drying, with excellent high temperature resistance and combustion resistance, mica tape has good flexibility under normal conditions, and is suitable for the fire-resistant insulation layer of various fire-resistant electromagnetic cables and coils, and has a wide range of applications.

Preparation of mica paper

The difference between various types of mica paper mainly lies in the different manufacturing methods of mica pulp, and the pulping methods mainly include calcination chemical treatment method, hydraulic pulping method, rubber roller crushing method and ultrasonic crushing method, etc., and the first two methods are more widely used.

The calcination chemical pulping method removes part of the crystalline water in the mica structure by calcination at high temperature, so that the mica sheet expands along the direction perpendicular to the cleavage plane, and the texture becomes soft, and then processed by chemical methods to fully split and dissociate the mica sheet, and then washed and graded into pulp. The mica paper pulped and copied by this method is called powder mica paper.

The process flow of hydraulic pulping method is: sorting (removal of impurities) of crushed mica - water separation - hydraulic pulping - hydrocyclone classification - dehydration and concentration.

The hydraulic pulping method uses a high-pressure jet of water to peel the mica flakes into fine flakes in a special cavity, and then carries out mineral processing to separate the mica flakes suitable for papermaking. This hydraulic pulping method is also known as the raw method. The natural mica paper made from mica pulp prepared in this way is called raw mica paper, referred to as raw paper.

Preparation of mica tape

The manufacturing method of mica tape can be divided into wet and dry process. The wet process refers to the asphalt mica tape that is bonded with asphalt, does not go through drying, and the volatile content is more than 6%, and this method has been eliminated. The dry method refers to the bonding of the reinforcing material and mica paper with a binder, and the mica ribbon material is prepared by baking.

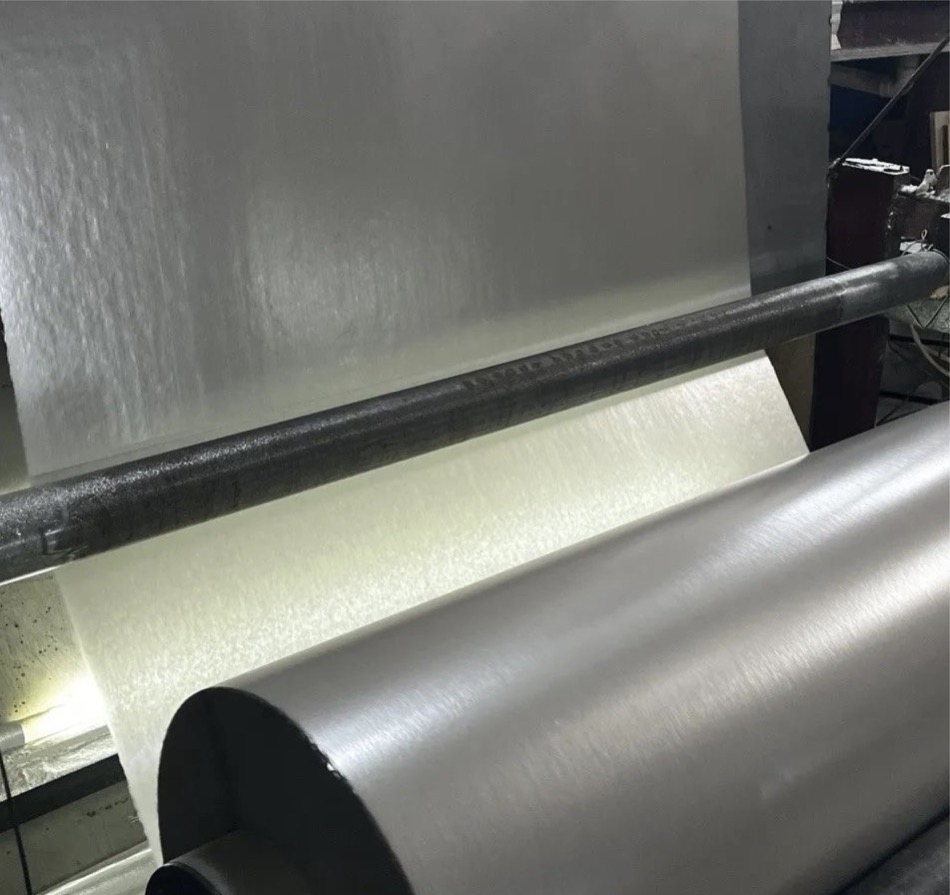

The production of mica tape is carried out on the mica tape sticking machine (most of the mica tape with multi-glue system uses calcined powder mica paper, which is called cooked paper; The mica tape of the less glue system uses large flake powder mica paper, called raw paper), first wear the reinforcing material, drive the glue, and then enter the oven to dry, and then wind, cut the tape and package.

Double-sided mica tape: mica paper is used as the base material, and glass fiber cloth is used as the double-sided reinforcing material.

Single-sided mica tape: mica paper is used as the base material, and glass fiber cloth is used as the single-sided reinforcing material.

Three-in-one mica tape: with mica paper as the base material, glass fiber cloth and OPE film as single-sided reinforcing materials.

Insulation properties at high temperatures: synthetic mica tape> phlogopite tape> muscovite tape.

Industrial use

In the industry, it mainly uses its insulation and heat resistance, as well as acid resistance, alkali resistance, compression resistance and peeling properties, and is used as an insulating material for electrical equipment and electrical equipment; Secondly, it is used in the manufacture of steam boilers, furnace windows and mechanical parts of smelting furnaces.

It is widely used in wire and cable, building materials industry, fire protection industry, fire extinguishing agent, welding electrode, plastic, electrical insulation, papermaking, asphalt paper, rubber, pearlescent pigment and other chemical industries. It has extremely high electrical insulation, acid and alkali corrosion resistance, elasticity, toughness and sliding properties, heat and sound insulation, and small thermal expansion coefficient.

New energy vehicles are a popular track in recent years, with the popularity of new energy vehicles, the application of separators and separators will be in a stage of rapid growth for a long time, and mica is an insulation, heat resistance, corrosion resistance, stable properties of environmental protection new materials, can improve the safety of separators and separators from the aspects of space stability and heat resistance.